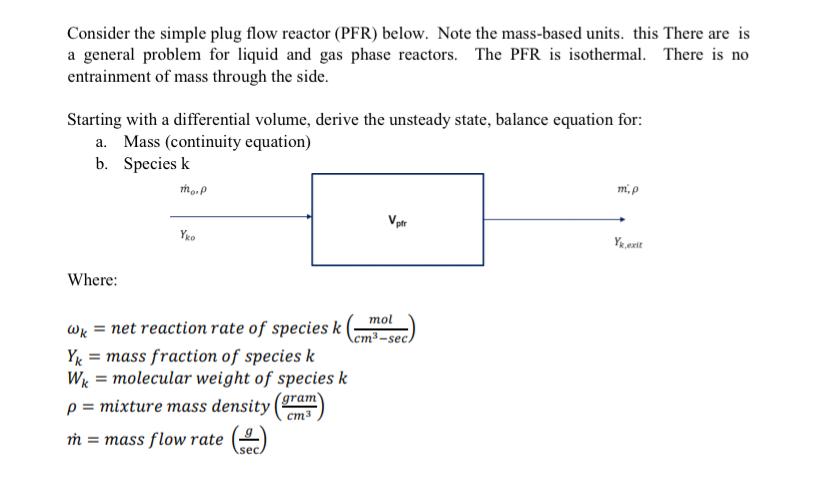

plug flow reactor equation

Although turbulent flow and axial diffusion cause a degree of mixing in the axial direction in real. B Show how to test this equation for an equimolar feed of A and B.

Solved Consider The Simple Plug Flow Reactor Pfr Below Chegg Com

ρCWii For a liquid dρ 0 dz dvρA dv dA dρ ρρAvAv0 dz dz dz dz Rearrange.

. This equation can be integrated along the length of the reactor to yield relationships between reactor resident time and concentration or conversion. 22 Segregated Flow Analysis The non-ideality of industrial and natural processes lead engineers to develop corrections to the ideal models in order to use them with less restrictions. DV area dz Mass flow rate is constant vAρconst.

Here polymerization and conversion reactions are performed in noncatalytic mode. In an ideal PFR is the absolute residence time for mass flowing through the reactor not the average residence time as in a CSTR. 62 which is the basic form of the design equation for a plug-flow reactor V is the reactor volume G is the total mass flow through the reactor Cao is the concentration of A at inlet in moles per unit mass of feed Xa is the fractional conversion of A and r is the reaction rate.

While reactors by themselves just define the above governing equations of the reactor the time integration is performed in reactor networks. A batch or plug-flow reactor maintains higher average concentrations of feed CFeed than a mixed-flow reactor in which the incoming feed is instantly diluted by the PRODUCT and BYPRODUCT. If ax a2 in Equations 564 and 565 the primary reaction to PRODUCT is favored by a high concentration of FEED.

The blue line is conversion as a function of temperature from the adiabatic energy balance. And we plan to test this with experiments in an isothermal plug flow reactor. Liquid is nonvolatile 7.

Derivation of the design equation for a plug flow reactor with second order kineticsPresented by Professor Alan Hall University of Huddersfield. The fixed-bed laboratory reactor is regarded as an ideal isothermal plug flow reactor. Dv 0 vv dz 0.

Select either an exothermic or an endothermic reaction. Essentially no back mixing is assumed with plugs of fluid passing through the reactor. Considering a first-order reaction the concentration equation will be 0 cc e kt.

A reactor network is therefore necessary even if only a single reactor is considered. The PFR is governed by ordinary differential equations the solution for which can be calculated providing that appropriate boundary conditions are known. Examples of real reactors that.

Plug-Flow Reactors are often used to simulate ignition delay times emission formation and catalytic processes. The design of Chemical Reactors is based on a few. Dv 11dA dρ v dz A dz ρdz For a normal pipe dA 0 and for a liquid dz dρ 0 dz Therefore.

Liquids gases and slurries. The plug flow model has many practical applications. Constant gas-phase concentration 4.

The black curve is the equilibrium conversion as a function of temperature from the vant Hoff equation. The reactor may be either isothermal or adiabatic or may have a specified axial temperature or heat. Compare ideal batch and ideal PFR mass balances.

In Chapter 2 governing equations for the plug flow reactor are first summarized for reference. The PFR model works well for many fluids. The number of moles of species i in is.

Add a Plug Flow Reactor to the flowsheet and connect the Feed and Product streams remember a shortcut for toggling into and out. Other simplifications used are. Chemical Reaction Engineering CRE deals with the design of Chemical Reactors to produce chemicals.

Diagram of a plug flow reactor showing flow in the z-direction. Chapter 5 discusses post-processing options. Chapter 3 discusses the mechanics of actually running the program and pre-processors and then Chapter 4 discusses the keyword input used in specifying the problem to be solved.

A Develop the isothermal performance equation for these kinetics for a feed of A B R and inerts. The step wise derivation of performance equation for Plug Flow Reactor and their typical characteristics are discussedPlug Flow ReactorFlow ReactorPerfor. A For this elementary reaction the rate wrt component A is.

The reactor model consists of the continuity equations for 1 N 2 CO NO O 2 CO 2 N 2 O and NO 2 in the gas phase 2 surface species adsorbed on the noble metal surface 3a surface species adsorbed on the ceria surface 3b species in the ceria. The polymerization of ethylene and the conversion of naphtha to ethylene are examples. DC d r C Ideal batch.

Comparing Equations R137-1 and R137-2 R137-2. Finite gas-liquid liquid-solid and intraparticle gradients Key Assumptions. Gaseous reactant is limiting 2.

Ad Find Plug Flow Reactor Equation. To achieve this form for plug-flow reactors we begin by applying the balance to a small differential volume in which there are no spatial variations Figure R137-1. One example is in the design of chemical reactors.

First-order reaction wrt dissolved gas 3. Both homogeneous gas-phase and heterogenous surface reactions can be accommodated. Which again is the characteristic equation of the plug flow reactor.

PLUG is a computer program that solves the coupled steady state continuity momentum energy and species balance equations for a plug flow reactor. The plug flow reactor is the second-most primary ideal reactor and is similar to the continuous stirred tank bioreactor. Catalyst concentration is constant 8.

Gas Limiting and Plug-Flow of Liquid 1. Plug-flow of liquid 5. Chemical Reactor is known as the heart of any chemical plant since the new chemicals are produced only in this vessel and the economics of the entire plant depends on the design of reactor.

The reaction occurs along the flow path. A catalytic process is used for the synthesis of ammonia. This results in differential equations that need to be integrated to find the reactor conversion and outlet temperatures.

The Langmuir-Hinshelwood equation you may or may not remember from CENG 390 is the form used for heterogeneous catalysis when you must worry about products or inerts using up active sites on the solid catalyst. DC dt r C Position in a PFR is equivalent to time in a batch reactor x C. In fact real reactors can be modeled as networks or combinations of multiple plug-flow and stirred-tank reactors Towler and Sinnott 2013.

A reversible reaction takes place in an adiabatic plug-flow reactor PFR.

Isothermal Plug Flow Reactor Part 1 Youtube

Introduction To Energy Balances For Plug Flow Reactors Youtube

Plug Flow Reactor Overview Youtube

Plug Flow Reactor Design Equation Youtube

Sizing A Plug Flow Reactor Pfr Youtube

Plug Flow Reactor Pfr Sizing And Conversion Example Youtube

Plug Flow Reactor With First Order Kinetics Performance Equation Youtube

L 2 1 Review What Size Reactors To

Plug Flow Reactor Vapourtec Ltd

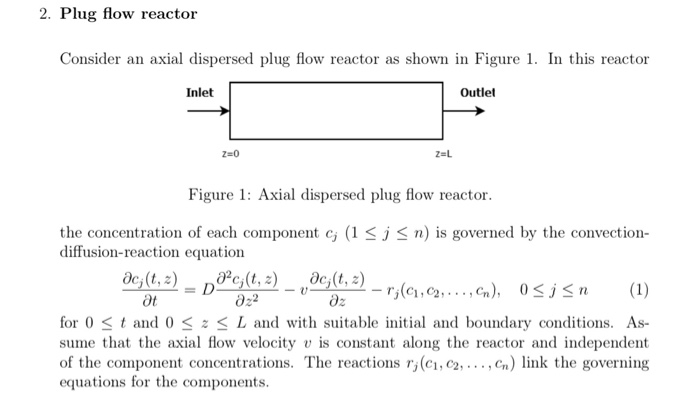

2 Plug Flow Reactor Ler An Axial Dispersed Plug Flow Chegg Com

Computational Scheme For A Plug Flow Reactor Defining The Function Download Scientific Diagram

Mole Balance On A Plug Flow Reactor Youtube

Rate Equation From Flow Vs Conversion Data Of Pfr

Plug Flow Reactor Model A Plug Flow Reactor Pfr Model Is Used By Justin Mitchell Medium

Design Equation Of Plug Flow Reactor Chemical Reaction Engineering Lecture 08 Hindi And Urdu Youtube

Solved 4 20 Points Consider A Plug Flow Reactor As Chegg Com